Location of the Anafon Hydro

The site of the Anafon Hydro lies in the Anafon valley in the Carneddau massif which rises immediately south of the village of Abergwyngregyn just inside the northern boundary of the Snowdonia National Park and 4 km west-south-west of Llanfairfechan. The Afon Anafon originates in Llyn Anafon, a small, disused reservoir 5.1 km south-east of Abergwyngregyn village. The river descends rapidly for 3.3 km through open moorland and then through Coedydd Aber Forest to join the Afon Rhaeadr Fawr immediately upstream of Bontnewydd. The two tributaries form the Afon Aber which runs a further 2.3 km through the village and farmland to enter the eastern end of the Menai Strait at Traeth Lafan. The total descent of the river from Llyn Anafon is 558 m over 5.6 km.

The intake weir will be situated 1.4 km downstream of the lake providing a catchment of 5.05 km2 and a head of 230m.

Technical Information

The Anafon Hydro is a high-head run-of-river scheme. A low weir feeds water into a buried 3 km pipe. The pipeline descends a total of 230 vertical metres, initially following the northern bank of the river which it crosses on a pipe bridge to the southern bank before entering the Coedydd Aber Forest. Here, it follows the forest track down to the turbine house located just inside the entrance to the Aber Falls National Nature Reserve.

The maximum power output is 270 KW but output is subject to variation in proportion to the flow of water in the river. Power produced by the turbine is exported to the National Grid via a new line to existing power lines approximately 150 m from the turbine house. This required an upgrade of the existing lines from the substation in the village about 1 km below the connection point.

A full feasibility study was conducted by John Howarth (John Howarth Hydropower Services), Dr Rod Gritten (Gritten Ecology) and subcontracted specialists. The resulting Environmental Statement was the basis for applications to Natural Resources Wales (NRW) for abstraction and impoundment licences and to the Snowdonia National Park Planning Authority. Planning consent was received in December 2013 and the Abstraction and Impoundment licences were issued in July 2014.

Financing the Project

Initial project development costs, including feasibility studies, planning consent application, application for water abstraction and impoundment licences, advice on administrative structures, legal fees, cessation agreement for grid connection, etc., were covered by grants, resources and support provided by Ynni’r Fro, Abergwyngregyn Regeneration Company, the Cooperative Community Energy Challenge, the National Trust, Gwynedd Werdd, the Waterloo Foundation, Wales Cooperative Centre, the Cooperative Enterprise Hub and Cooperatives UK.

John Howarth Hydropower Services estimated the design and construction costs for the Anafon project at £1.25 million made up as follows:

- Project development costs - £60,000

- Project construction costs - £1,055,000

- Contingency - £134,000

In the event, the Anafon Hydro was constructed for a total of £1.1 M, almost exactly in line with John Howarth’s estimate.

The capital funding for the project came from two sources. On September 13th 2014, Ynni Anafon Energy launched a community share issue which attracted investment of £450,900 by its closure in March 2015, with the majority of shareholders living locally but with others from across the UK and abroad. Additional funds were raised through a bank loan of £545,000 from Charity Bank, repayable over 15 years.

Click below to see confirmation of consent documents;

Planning Consent

Abstraction and Impoundment Licences

Ofgem Feed in Tariff Accreditation Confirmation

HMRC letter of confirmation of eligibility for SEIS/EIS tax relief

Building the Anafon Hydro

Following a tendering process in 2014, two contractors were engaged to build the hydro: Gelli Civil Engineering to build the turbine house and the weir and Kevin Williams Earthworks to install the pipeline.

After a village ceremony on 4 May 2015 at which the oldest and youngest residents born in Abergwyngregyn together cut the first turf, Gelli arrived on site on 5 May to commence work on the turbine house. Kevin Williams started work on the pipeline in the Anafon valley on 11 May.

Construction proceeded smoothly and both contractors finished work at the end of September 2015.

However, Scottish Power failed to schedule the work to install their substation in the turbine house and to upgrade the power lines from the village to coincide with the completion of construction. They commenced work on the substation in the middle of November but the work on the power line upgrade did not start until towards the end of that month by which time the weather had broken causing further delays.

The upgrade and connection to the grid were eventually completed on 27 November 2015 and work to commission the plant started immediately. Commissioning was completed on 30 November with the successful completion of the G59 test and the Anafon Hydro commenced full generation and export of electricity to the grid on 1 December, one month earlier than our original target date.

Income from the Anafon Hydro

For the first 20 years, our financial projections indicate that the Anafon Hydro will generate gross revenue of approximately £200,000 a year, made up from the sale of electricity and the Government subsidy to renewable energy generation, the Feed-in-Tariff. Thereafter, the income will be derived solely from the sale of electricity except in the unlikely event that there are further government subsidies.

After servicing our bank loan and the deduction of running costs, profits that are generated during the first two years of operation will be allocated to building up a number of reserves in accordance with the conditions of our bank loan and to cover emergencies. From the third year, YAE will commence payment of interest to our shareholders and disposable profits will be transferred to the charity, Dŵr Anafon, for distribution for community benefit.

For the first 15 years until our bank loan is paid off, we expect these disposable profits to be in the region of £30,000 to £40,000 p.a. From Year 16 to Year 20 when our Feed in Tariff ends, this figure should rise to in the region of £80,000 to £90,000. However, during this period, we are committed, under the terms of our lease, to make a donation of £25,000 p. a. to the National Trust specifically for conservation work in the Carneddau massif in which the hydro is located. The amount available for local community benefit will therefore rise to approximately £55,000 to £65,000.

After Year 20 when the Feed in Tariff ends, income will depend on the price of electricity which cannot be predicted.

Photographic record of the construction of the Anafon Hydro

Work starts on site!

Preparatory work on site will start on 3 March 2015. This will include felling a number of mature conifers in the Aber Forest to create a 100 m long corridor for the pipeline as it enters the forest. The work is expected to take about 3 weeks.

Paul Smith (Alfa Tree Services) and his team start work clearing the corridor.

Paul discusses the work with Kevin Williams, pipeline contractor, John Howarth, project engineer, and Dr Rod Gritten. ecological clerk of works.

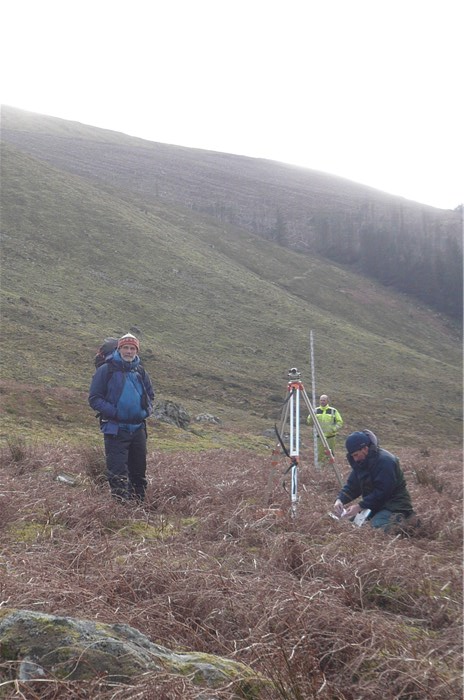

Final survey of the pipeline route.

Dr Rod Gritten, Kevin Williams, and John Howarth conduct a final survey of the pipeline route through the heath in the Anafon Valley, a particulary sensitive section. As a reesult of this survey, minor changes were made to the route.

The weather closes in!

Felling complete along pipeline route through Coedydd Aber forest

Alfa Trees Services completed felling the 100m section of the pipeline route through mature Sitka Spruce into Coedydd Aber forest on 17 March 2015, 3 days ahead of schedule.

Independent technical assessment of the Anafon Hydro Project

Derwent Hydro engineers carry out an independent technical assessment of the Anafon Project for Charity Bank, our probably main lender.

YAE chooses contractors to build the Anafon Hydro Project

Following the tendering process, the Board will be awarding the contracts to build the Anafon Hydro to two contractors. Gelli Civil Engineering, Tremadog, will build the weir and turbine house and Kevin Williams Earthworks, Bontddu near Dolgellau, will install the pipeline.

Gelli Civil Engineering have wide experience of civil engineering work near and in rivers and Kevin Williams installed the pipeline for the Harnog Hydro and so is experienced in pipeline installation and reinstatement work in sensitive environments.

Both contractors expect to start work in early May.

NRW ecologists, reserve managers and regulators on site

NRW ecologists, reserve managers and regulators meet John Howarth, Dr Rod Gritten and our contractors for a final site meeting to discuss the Construction Method Statement - 1 April

Underway at last!

The Abergwyngregyn community gathers at the turbine house site for the ceremony to cut the first turf - 4 May.

Eirlys Williams and Emily Jones (4 months old), the oldest and youngest current residents born in Aber, cut the first turf.

The contractors start work.

The turbine house and weir contractors, Gelli Civil Engineering, arrive at the turbine house site - 5 May.

The site cabins go in.

Artist's impressions of how the turbne house will look by Aber resident, Helen Flook.

The turbine house from the gate into the Aber Falls reserve.

The view of the turbine house as you return from the Falls along the main footpath.

7 May 2015

The access track to the Turbine House goes in

9 May 2015

The bank is cut back to accommodate the Turbine House

12 May 2015

Excavation for the Turbine House continues under the watchful eye of archaeologist, Ian Brooks, carrying out his watching brief. The only finds so far: two Northern Dairies milk bottles!

14 May 2015

Excavation for the foundations of the turbine base is complete.

The outflow pipe from the turbine is installed.

16 May 2015

Shuttering for the foundations of the turbine base and the first concrete is poured.

26 May 2015

Excavation for the sub-station foundations.

29 May 2015

The sub-station floor is cast.

John Howarth inspects the foundations.

10 June 2015

The brickwork for the sub-station underfloor cable ducts is completed - 8 June.

In the meantime, Kevin Williams, our pipeline contractor, has been busy on the pipeline in the Anafon Valley.

Ten metre sections of the polyethylene pipe are welded together to form 130m lengths ready for installation.

The welding machine in action.

A temporary track is put in across the river.

Work starts on the installation of the pipeline on the mountain - 2 June.

The trench for the first 130m length of pipe is opened - 3 June.

The pipeline is dragged up the mountain

and drawn into its trench.

The first section in position in its trench.

The trench is filled

The trench for the second 130m section of pipe is opened.

The first 2 sections of pipeline are welded together.

15 June 2015

Adjusting the reinforcement for the turbine house floor.

16 June 2015

The turbine house floor is cast.

In the meantime, on the mountain:

The first 400m of the pipeline is installed on the southern bank of the Anafon River.

And reinstatement is underway.

The reinstated pipeline route begins to recover.

The first section of pipe is installed on the north bank of the Anafon.

Work begins clearing the corridor through the forest for the pipeline.

23 June 2015

The walls of the substation almost halfway there.

The base for the generator is cast.

Meanwhile, on the mountain:

The pipeline on the south bank of the Afon Anafon is installed and the mountainside reinstated.

Levels for the pipeline along the initial sections of the pipe below the weir are particularly critical as the drop is only 1 in 165. John Howarth makes a final check of the levels.

The cut for the pipeline comes within sight of the weir location (by the trees in the background).

The pipe is eased into its trench. Kevin Williams has only one more short section of polyethylene pipe and the steel pipe crossing the river to install before he moves to the forest. Gelli will install the final section of the pipeline connecting to the weir when this is built.

The installation of the pipeline on the north bank of the Anafon nears completion with much of the route reinstated.

26 June 2015

Emyr Roberts, CEO Natural Resources Wales, and Derek Stephen, Energy Deliver Programme Manager, visited the project yesterday.

Aeron, Gelli's Site Manager, explains the site to Emyr Roberts.

Emyr Roberts and Gavin Gatehouse at the Turbine House site.

29 June 2015

Last few courses of bricks on the turbine house substation.

Meanwhile, on the mountain:

Steel pipe for the river crossing is delivered on site.

The pipe is positioned across the river.

30 June 2015

The pipes are aligned for the final connection at the pipe bridge.

The connector is bolted up.

All connections completed on the pipe bridge.

The pipe bridge across Afon Anafon in position.

3 July 2015

Turbine house substation roof slab is cast.

Last few courses of blocks on the turbine room walls.

Meanwhile, on the mountain:

Pipe bridge completed and the surrounding slopes reinstated.

The pipe bridge.

and in Coedydd Aber Forest:

Kevin Williams moves his team down from the mountain and the pipe welding station is set up again.

Welding the connector between thinner and thicker walled pipe.

6 July 2015

The reinstated heath is recovering well after 3 weeks.

15 July 2015

Rafters supporting the sedum (turf) roof of the turbine house are installed.

The turbine house comes into view as you return from the Aber Falls.

Meanwhile, on the pipeline route:

The cutting for the pipeline trench from the forest reaches the end of the pipeline on the mountain.

The trench is cut and the pipe dragged up onto the mountain.

The pipes meet and the connection is made - 9 July.

The pipeline reaches the forest track where it will be buried in the uphill bank.

The thin-walled pipe in the upper section of the pipeline is replaced by thicker-walled pipe for the lower sections to withstand the increasing pressure.

The bank of the forest road is cleared ready for installation of the pipeline.

and Gelli have started work at the weir site:

The temporary access track to the weir site is put in

and reaches the site of the weir.

The first channel to divert the river to the north bank is opened up.

The river is diverted to allow the digger to install the pipes on the south bank which will carry the flow while the weir is built in the river bed.

29 July 2015 - a memorable day!

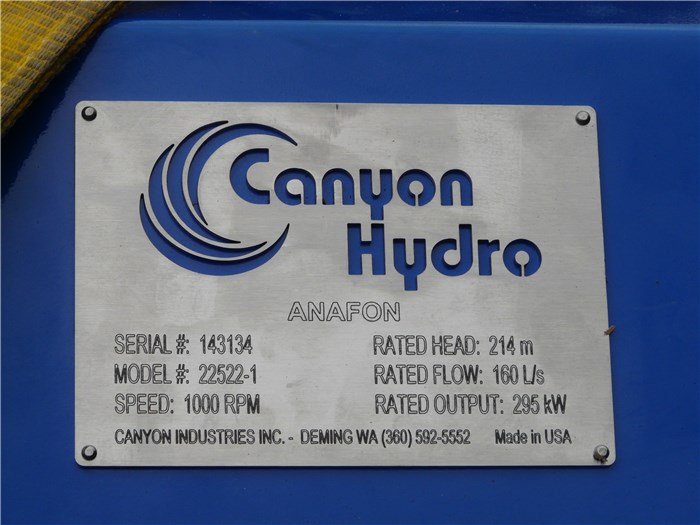

Our turbine arrives in Abergwyngregyn from the USA via Liverpool Docks.

The turbine is lifted from its container,

driven up through the village to the turbine house

and manoeuvred through the doors.

It is aligned with its mounting

and lowered into position.

Meanwhile, at the weir site:

The trench for the diversionary pipes is prepared on the south bank of the river.

The pipes are installed and the river is diverted through them.

4 August 2015

The weir construction site

With the river diverted, the reinforcement for the weir foundation is installed

and the foundation is cast with the reinforcement for the weir wall in position.

11 August 2015

At the weir

The shuttering for the weir wall is in place

13 August 2015

At the weir site

The shuttering is removed to reveal the structure of the weir wall.

Meanwhile at the turbine house

The roof is on ready for laying the sedum turf.

The generator and control equipment cabinets are installed.

The manifold connecting the pipeline to the turbine is in position

and the outlet returning the water from the turbine to the river nears completion.

19 August 2015

In Coedydd Aber Forest

The installation of the pipeline reaches the point where the overhead power lines cross the valley

and the bank is reinstated.

The final strings of thick-walled pipe are welded

and the last section of the pipeline awaits installation at the bottom of the forest road.

22 August 2015

At the weir site

The tank and pipework are installed and the pipeline anchor block cast

24 August 2015

At the turbine house

The finished turbine house viewed from the gate into the Aber Falls Reserve

compared with the artist's impression published earlier.

The finished turbine house viewed from the path returning from the Aber Falls

compared with the artist's impression.

In Coedydd Aber Forest

The steel pipe to take the water down the bank to the turbine house is delivered on site while Alfa Tree Services carry out some last minute tree clearance.

28 August 2015

On the pipeline

The steel pipe running down the bank to the turbine house is installed.

The last section of the polyethylene pipe is connected to the steel pipe down the bank to the turbine house.

The exposed section of steel pipe is encased in its plastic insulating cover.

8 September 2015

On the pipeline

Kevin Williams encounters rock in Coedydd Aber Forest.

The final section of pipe in its trench through rock.

At the weir

Stone walling in progress on the southern bank.

The oak cladding of the weir walls is complete.

Heavy rainfall overwhelms the diversion pipes and floods the working area temporarily - 6 September 2015.

The stone walling on the south bank is completed and the trench is dug for the last section of pipe to the weir.

The pipe connecting the buried pipeline to the weir in its trench.

9 September 2015

At the Turbine House

The Ditch Witch, Scottish Power's directional drilling rig, is tracked up through the village to the turbine house.

The Ditch Witch in position behind the turbine house.

The rig starts drilling under the river for the grid connection cable - 2 September 2015.

The drill emerges near the pole which will receive the grid connection on the other side of the river after passing through bed rock 4 m below the river bed.

The drill head.

The red plastic duct for the grid connection cable and earthing wires are attached to the reversing head.

The drill rod and spinning reversing head, with the plastic duct and earthing wires attached, is pulled back down the drill hole.

The plastic duct for the grid connection cable is dragged back under the river to the back of the turbine house.

15 September 2015

At the weir

The coanda screen through which water is extracted from the river flow and diverted into the pipeline is installed - 9 September 2015.

Detail of the coanda screen showing the slots through which water is abstracted.

The diversion pipes are capped and the weir is flooded.

Turbidity downstream 1 hr after the weir was flooded; by the time the flow reached the pipe bridge, the flow was clear.

The flow is clear at the weir 4 hr after flooding.

The weir in its landscape

24 September 2015

On the pipeline

The pipe is aligned for the final joint. Thirty metres of surplus pipe can be seen in the background, all that's left from the 3 km pipeline!

The connector is "eased" over the joint

The welding coils built into the connector are activated to complete the final joint in the pipeline.

The upper section of the pipeline is flushed with water - 23 September 2015.

The completed pipeline is flushed with water.

29 October 2015

On the pipeline

Third valve lucky! Two by-pass valves proved faulty but the third, being installed here, works - 14 October

The now completed pipeline is filled and the pressure of 22.7 bar at the turbine house is maintained indicating that there are no leaks - 15 October

The pipeline is pressure tested. Water is pumped into the pipeline at the weir and the pressure raised to 23.7 bar. No faults are detected - 26-27 October

After the pipeline has been pressure-tested, all exposed joints are buried and the area behind the Turbine House reinstated - 29 October

The forest road above the Turbine House is reinstated - 29 October

The bank over the buried pipeline through Coedydd Aber Forest recovers well.

20 November 2015

At the Turbine House and on the Powerline

Scottish Power contractors work to upgrade the powerlines above the village to take the power we generate - 16 November

The grid connection cable is passed through the duct under the river and buried in a trench up to the pole where it connects to the grid. 17 November

Emerging from the duct behind the Turbine House, the cable is connected into the sub-station - 19 November

Scottish Power complete the installation of the sub-station at the Turbine House - 20 November

Meanwhile, the heavy November rainfall means that we are missing significant generation time - 14 November

26 November 2015

On the Powerline

Scottish Power contractors complete the upgrade of the powerlines from the village to the pole that will take the connection from the Turbine House - 26 November

The cable running under the river from the Turbine House is run up the pole to connect to the overhead line - 26 November

28 November 2015

At the Turbine House

The underside of the turbine from the sump: the stainless steel Pelton wheel, the deflector which deflects water away from the wheel and stops the turbine if a fault occurs and, in the back wall of the housing, the spear valve which opens to direct the high-pressure jet of water onto the wheel to spin it at 1,000 rpm - 27 November

The turbine reaches its operating speed of 1,000 rpm during commissioning tests - 27 November

Generating 230 volts on each of the three lines - 27 November

The Anafon Hydro is 'on grid' and exporting electricity - 27 November

The 'Gang of Three' raise a glass! 28 November

From the left: our engineers, Dave Roberts and John Howarth (with Brock), Liz Gatehouse (with Molly - just visible), Hywel Thomas, Ian Crystal and Jacqui Bugden, Gavin Gatehouse - 28 November

Anthony Clark (Scottish Power) and Dave Roberts carry out our G59 test. We passed which allows us to register for Feed in Tariff payments from today - 30 November

1 December 2015

Mission Accomplished! The Anafon Hydro is up and running a month ahead of schedule and exporting 270 kW to the grid.

Ein cefnogwyr

Cydnabyddwn yn ddiolchgar gefnogaeth y canlynol: